BLOCK (MONOLITHIC) CATALYSTS OF CELLULAR STRUCTURE FOR DIFFERENT PURPOSE

Catalysts for the disposal of toxic combustion products (СО, NOx, CnHm) of natural gas

Catalysts are designed for purification of gas-air mixtures, which are used to heat greenhouses and fertilize indoor plants with carbon dioxide, formed during the combustion of natural gas in flares of gas burners, gas boilers, picket furnaces and more.

The catalytic filter unit performs high-efficiency purification of hot air from toxic components (carbon monoxide, nitrogen oxides, hydrocarbons), i.e. CO2 and H2O can be sent to greenhouses for plant nutrition.

Characteristics:

-

- • 80-90% of purification from СО, NOх, CnHm at 150-550 °C and gas flow rate 12000-100000 h-1

-

- • chemically and mechanically resistant (compressive strength up to 120 kg/cm2)

-

- • low gas-dynamic resistance

-

- • blocks (rectangular prisms) of cellular structure, size 70 × 70 × 300 mm, holes 7 × 7 mm (custom shape and size can be changed)

- • passive nozzle for the air heater, which does not affect the gas supply system, power supply, control system.

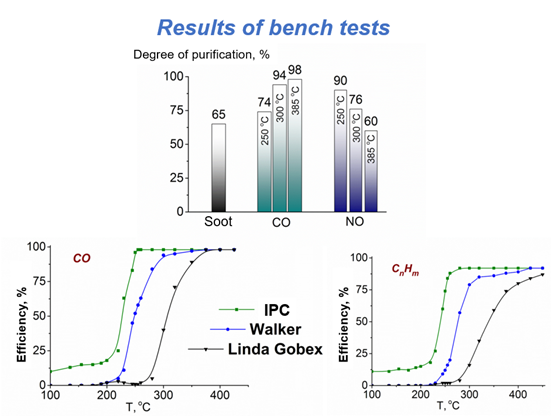

Catalysts of three-component purification of exhaust gases of internal combustion engines of cars (catalytic converters)

Patent of Ukraine № 79027, № 102710

The developed technology of catalysts allows to reduce the content of platinum metals in 2-3 times in comparison with analogues without decreasing of purification efficiency and service life of neutralizers. Catalysts are characterized by low temperatures to achieve high degrees of purification from toxic components (170-300 °C) and resistance to sulphur compounds..

Characteristics:

-

- • degree of purification from CO is 93-95%, NOx ‒ 98-99%; CnHm ‒ 85-90%

-

- • thermal stability (up to 1000 °C)

-

- • stabilization of active components of catalysts (1-10 nm)

- • blocks of defined cellular structure with longitudinal channels that provides low gas-dynamic resistance

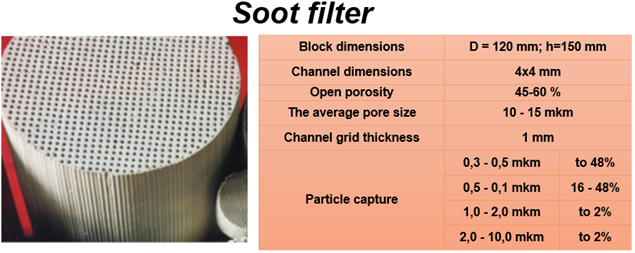

Soot filters with a catalytic covering for clearing of emissions of diesel engines from solid microparticles

The filters ensure the combustion of soot microparticles in a continuous mode at operating temperatures of gas emissions..

Characteristics:

-

- • blocks of cellular structure with alternately closed cells from the ends (with a chessboard pattern), which provides uniform filtration of gas flow through the wall of the block

- • catalytic coating (complex composites based on oxides of transition metals (Mn, Cu, Co, Cr)) provides an oxidation of fine carbon (soot) already at the temperatures of the exhaust gases of the internal combustion engine with the participation of oxidants present in the gas emissions (O2, NOx, H2O, CO2).

Tests on motor installations («Malyshev Factory» (Kharkiv), High Pressure Combustion Laboratory of the Pennsylvania State University (USA), «Melitopol Motor Plant» (Melitopol)) showed that the efficiency of the developed systems of catalytic neutralization of exhaust gases is not inferior to foreign analogues.

Catalyst for the selective reduction of nitrogen oxides in oxygen-containing exhaust gases

Patent of Ukraine № 85669

It is designed to neutralize nitrogen oxides (NO, NO2) in the exhaust gases of automobile engines operating in the mode of “depleted” fuel mixture, diesel-electric units, etc.

In comparison with analogues, the block catalyst is characterized by greater availability of active components, higher productivity, lower gas-dynamic resistance and reduced content of precious metals.

Characteristics:

-

- • ceramic block matrices of cellular structure from synthetic cordierite

-

- • degree of purification from nitrogen oxides ≥95% at 250-400 °C

-

- • oxygenates are reducing agents (including bioethanol)

- • provide purification from CO and hydrocarbons (products of incomplete combustion of fuel), involving them in the process of reduction of nitrogen oxides

Catalysts for the selective reduction of nitrogen oxides with ammonia

Patent of Ukraine № 19317, № 32552

Catalysts are designed for purification of exhaust gases of industrial heating units (CHP, TPS), gas turbines and other units from nitrogen oxides in the presence of oxygen.

Characteristics:

-

- • ceramic block matrices of cellular structure from synthetic cordierite, aerosilogel, etc.

-

- • the degree of reduction of NO by ammonia at an exhaust gas temperature of 250-400 °C reaches 80-100%

- • resistance to poisoning by sulphur compounds

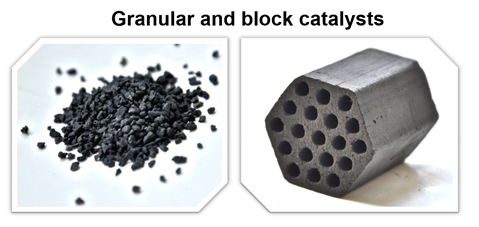

Together with “Catalyst” (Kamianske) granular and block catalysts for the selective reduction of nitrogen oxides with ammonia in the exhaust gases of nitric acid production developed:

-

- • highly active in the reduction of nitrogen oxides to molecular nitrogen

-

- • provide decomposition of residual ammonia

- • do not contain toxic oxides of vanadium and precious metals

STRUCTURED CATHALISTS FOR COMBINED REFORMING OF C1-C4-ALKANES WITH THE PREPARATION OF HYDROGEN AND SYNTHESIS GAS

Patent of Ukraine № 108461

They are designed for the processes of steam, carbon dioxide conversion of methane to produce hydrogen and synthesis gas (СО+Н2) for the subsequent synthesis of ammonia, methanol, diethyl ethers, Fischer-Tropsch synthesis.

Characteristics:

-

- • cellular structure catalyst with low content of active components and low gas-dynamic resistance

-

- • allows to implement the process of combined reforming of С1-С4 alkanes with the participation of О2, Н2О, СО2

-

- • allows to receive synthesis gas with an adjustable ratio of Н2/СО from 1 to 3

- • possibility of realization of an autothermal mode

In comparison with analogues, the catalyst is cheaper to operate, has a lower content of active ingredients, it is characterized by high productivity, resistance to carbon and sulphur-containing compounds, low gas-dynamic resistance, a wide range of operating temperatures (500-1000 °C), and has no precious metals. In the process of steam conversion of methane the catalyst predominate foreign analogues (DIAP-16, Haldor Topsoe R-67-7H).

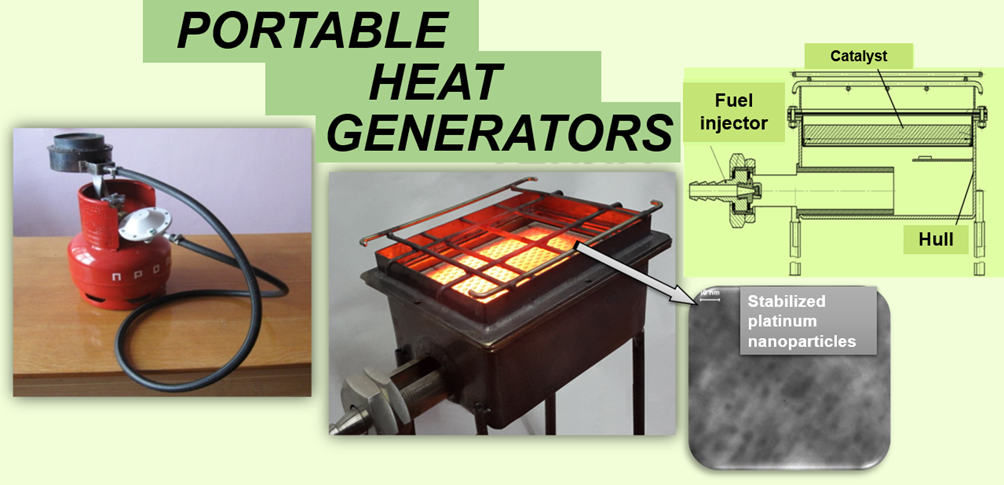

CATALYSTS OF FLAMELESS COMBUSTION OF NATURAL GAS AND GAS CONDENSATE IN HEAT GENERATORS

Patent of Ukraine № 77552, № 103813

They are designed for combustion of gaseous hydrocarbon fuels (С1-С4 alkanes) in portable and industrial catalytic heat generators, as well as for use in the systems of catalytic purification of exhaust gases from hydrocarbon impurities (in chemical, petrochemical and metallurgical industries).

Characteristics:

-

- • complete oxidation of hydrocarbons at temperatures up to 750 °C

-

- • low gas-dynamic resistance to the reaction flow

-

- • mechanical strength (50 MPa)

-

- • low content of active ingredients due to their uniform distribution on the surface of the secondary carrier

-

- • no loss of active components during catalyst operation

-

-

- • absence of CO and NOx in combustion products, which allows the use of catalytic heat generators in rooms with limited air exchange (in greenhouses, dugouts, etc.)

-

CATALYSTS FOR LOW TEMPERATURE PURIFICATION OF AIR AND GAS EMISSIONS FROM OZONE

During the gas passing through the catalyst bed there is a stable decomposition of ozone to oxygen at room temperature.

The catalyst provides purification from ozone of:

-

-

-

- • air and ventilation gases with a relative humidity of 100% (temperature 15 °С, ozone concentration 500 mg/m3). The degree of ozone conversion is 95% (at 40 °C and a volumetric rate of 7000 h-1)

-

-

-

- • gas emissions generated during the processing of polypropylene film by corona discharge before applying color printing. The degree of ozone conversion is 95-98% (at 20 °C and a volumetric rate of 20000 h-1)

-

-

- • electron accelerator ventilation air with ozone content up to 200 mg/m3. The concentration of ozone after passing through the catalyst bed decreases by 2 orders of magnitude (at 20 °C and a volumetric velocity of 10000 h-1)

-

Industrial use (Dnipro water supply station of Kyiv; “Ukrplastyk”, etc.) has shown that the developed catalysts provide stable ozone treatment.

CRUST-TYPE STRUCTURED CATALYSTS FOR PURIFICATION OF GAS EMISSIONS FROM CARBON MONOXIDE AND ORGANIC COMPOUNDS OF DIFFERENT CLASSES

Patent of Ukraine № 56859

Catalysts are designed to purify gaseous emissions from highly toxic organic compounds of various classes, primarily aromatics (benzene and its homologues), including polycyclic hydrocarbons (naphthalene, anthracene, benzopyrene), carbon monoxide and other toxic compounds.

Characteristics:

-

-

-

- • catalysts of the crust-type structure with adjustable depth of penetration of active ingredients into the depth of the granule

-

-

- • resource-saving manufacturing technology ensures the use of active ingredients that contain platinum group metals, with the highest efficiency in the target process

-

Catalysts have passed industrial tests and are used at the Kyiv plant of medicines (purification from a mix of organic solvents), “Poltava diamond plant” (purification from phenol, formaldehyde, acetone, carbon monoxide) and other enterprises.

In terms of their performance characteristics, the developed catalysts surpass those known in the CIS countries.

CRUST-TYPE STRUCTURED CATALYSTS FOR SELECTIVE REDUCTION OF NITROGEN OXIDES BY AMMONIA

Patent of Ukraine № 145558

The ACZ-CT catalyst is designed for purification of exhaust gases in productions, the technology of which is accompanied by emissions of nitrogen oxides into the atmosphere.

Characteristics:

-

-

-

- • Extruded granules of alumina containing (%wt.): CuO – 10–14, ΖnΟ – 5 ± 1.

-

-

- • Reduction of CuO content in the catalyst without loss of activity.

-

The technological process of manufacturing of the developed ACZ-CT catalyst in the conditions of “Catalyst” (Kamianske) has been worked out. Tests on a pilot plant on the current unit of production of non-concentrated nitric acid of the holding “Ostchem” showed that the developed catalyst provides a reduction of residual nitrogen oxides in the purified gas to the 0.001-0.002%vol. and almost complete absence of ammonia.

The ratio of NH3/NO = 1,2 is optimal to ensure the proper level of purification from nitrogen oxides, which is lower compared to the known industrial catalyst, which reduces the amount of ammonia for purification of exhaust gases in the nitric acid industry.